Now on to the dust panel construction, the whole sub panel assembly is made of Yellow Poplar. Behind the Mahogany ‘drawer blade’ (or drawer divider) is the drawer blade sub-back, it gets glued to the front drawer blade and rides in a shallow 1/8″ deep x 7/8″ wide dado in case side. The drawer blade sub-back receives a 1/4″ w x 1″ deep rabbit, as does the rear drawer blade, the rear drawer blade also is dovetailed into the case sides using a blind sliding dovetail..

Each of the drawer divider rails received a 1/4″ x 1″ tendon on both ends, we cut the tendons on the tablesaw using a dado stacked cutter. The one inch thick piece of MDF makes sure the tendon shoulder is properly spaced, but gives us proper clearance when using the miter gauge. Using the miter gauge and the rip fence (without a spacer) is not a safe practice, it is a kickback waiting to happen..

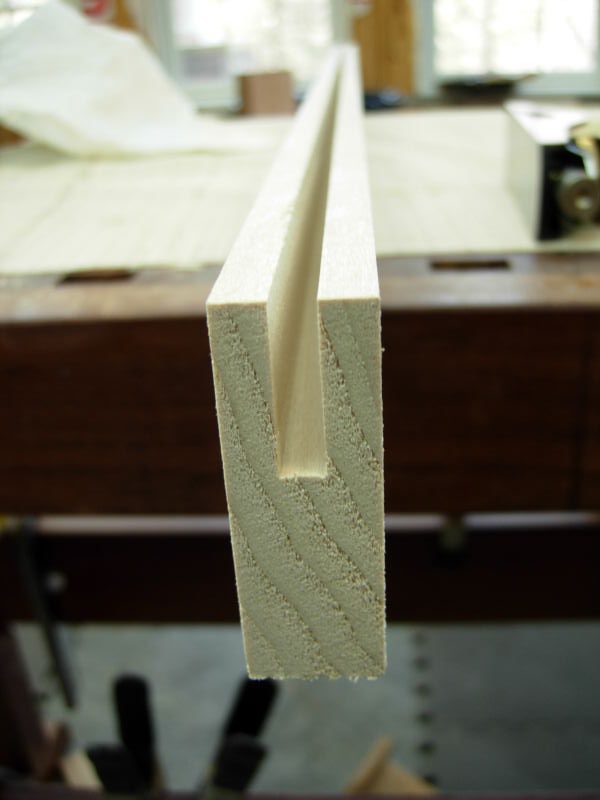

And finally this is what the semi-finished drawer blade sub-back (we are still missing the actual dust panels themselves) looks like. The gap at the back is intentional, it allows for the case sides to expand and contract.